The Best Leak Detection Test Is When The Refrigeration System Is

The best leak detection test is when the refrigeration system is. The testing equipment is easily interchangeable to allow the test of different types of components more than 50 in the specific. In the refrigeration industry components and systems must be leak tested to ensure that refrigerant leakages are below specified limits. This indicates that there is still a little moisture in the system being boiled off.

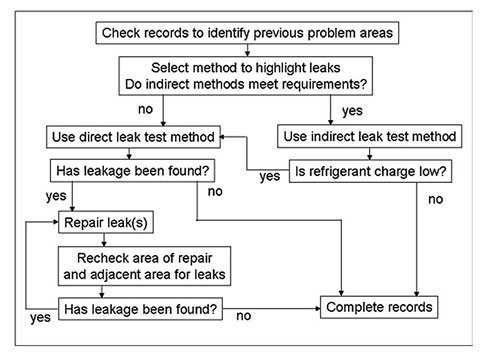

This Good Practice guide is intended to cover the identification of leaks using Nitrogen for refrigeration systems which are already in operation and are known to have undergone a strength pressure test. Ad Leak detectors for all types of packages - with modified atmosphere MAP or vacuum. Direct Leak Detection.

You pull a vacuum on a refrigeration system more than once allowing some dry nitrogen back into the system between each procedure. The Elitech WJL-6000 is the best HVAC Freon leak detector around. Begin to rise the best leak detection test is when the refrigeration system is.

Perform a nitrogen purge and pressure test with every new installation to ensure no leaks are present. This inspection method cant position precisely because the leakage point is usually very tiny and many parts of the refrigeration system are barely visible. Ensure ALL valves are capped.

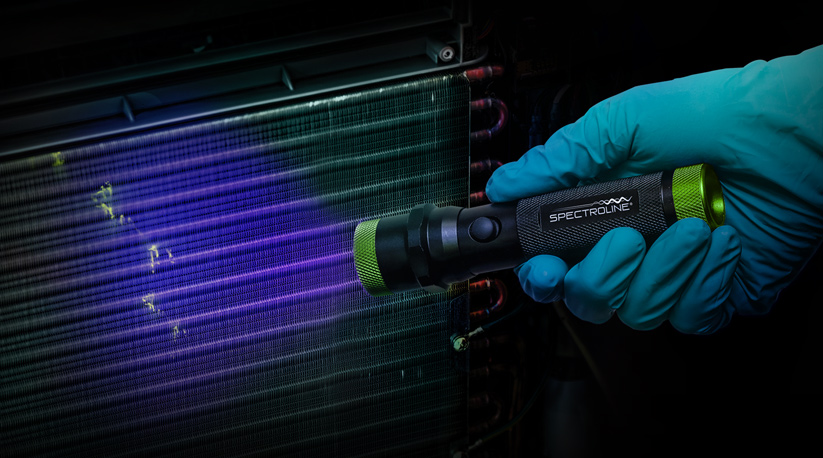

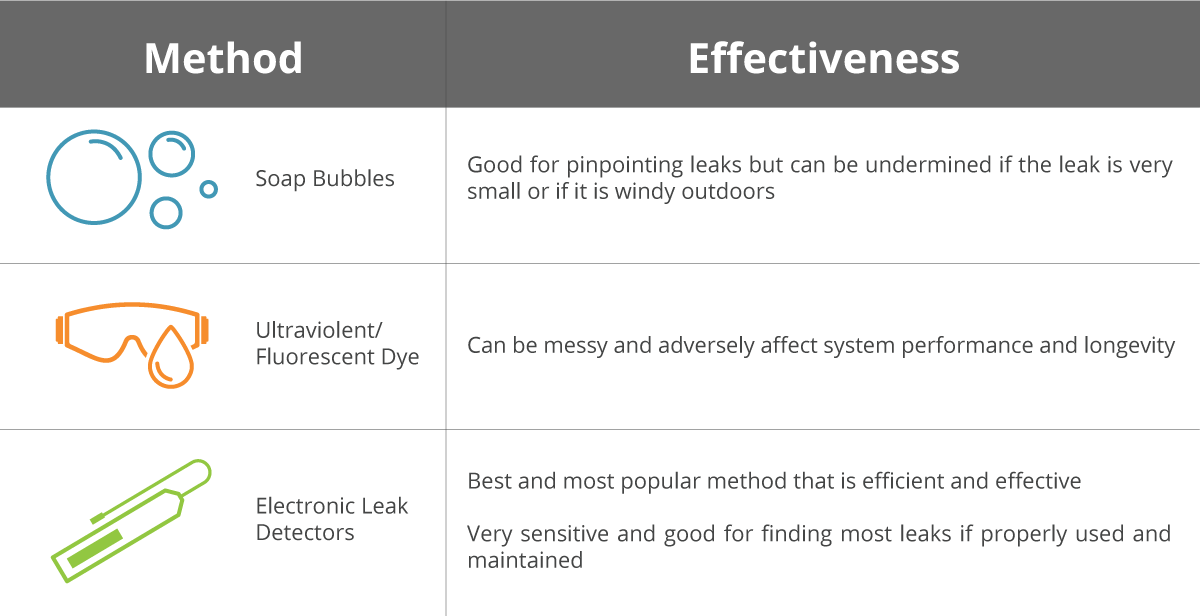

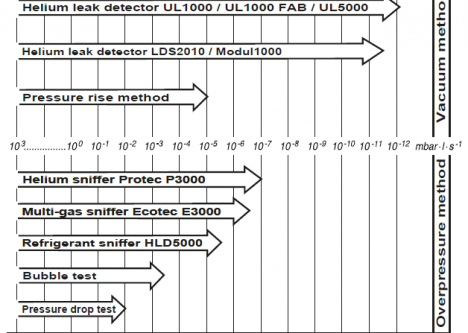

Local Leak Detection with Electronic Leak Detectors Ultrasonic Sound Hand held leak detectors using the detection of pressure escaping through the leak source by listening for gas leaking. The three basic functions of leak testing are 1 determining if there is leakage or not detection 2 measurement of leak rate and 3 leakage location. Install a refrigerant leak monitoring notification and alarm system to detect leaks between regular leak inspections.

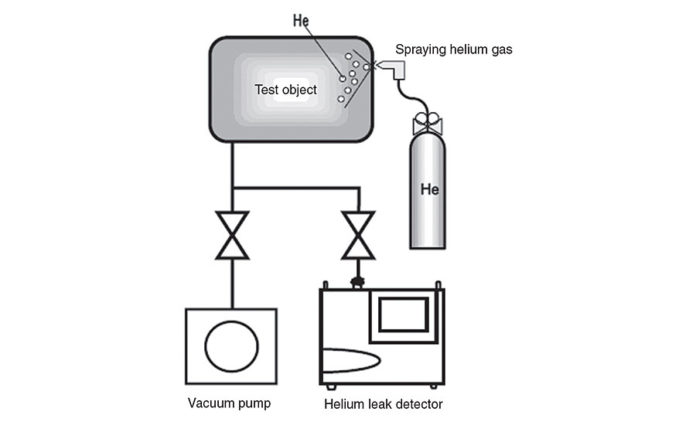

Two different types of leak detection system can be considered. The system can be used with manual loading unloading from the front it is equipped with a push-button and light safety barriers or with automatic loading unloading from the rear side by robot. If the system is short of refrigerant decant the remainder of the charge and replace the line tap with a schrader before re processing the system.

Theres no maximum period of time between leak checks on. In all situations the leak test can include checks made with one or more of three direct.

If you find somewhere in the system with oil traces probably that is the leakage point.

Bubbling in the liquid line sight glass. 200 to 500 microns. Ideal for retrofitting leak detection into existing buildings. Sometimes it may be conducted onboard after doing major repair works in cooling lines. Direct Leak Detection. If the system is short of refrigerant decant the remainder of the charge and replace the line tap with a schrader before re processing the system. It will require a bit of training and practice to get the system to pinpoint the leak. The testing equipment is easily interchangeable to allow the test of different types of components more than 50 in the specific. Except where used as a trace gas fluorocarbon refrigerant must not be put into a system for the purposes of pressure related leak testing.

Theres no maximum period of time between leak checks on. System not achieving capacity room over temperature. If a vacuum ya s been pulled on a system and there is a leak the vacuum gauge will. Before doing these test make sure that the system is shut and all the refrigerant is collected Pressure Test. If the system is short of refrigerant decant the remainder of the charge and replace the line tap with a schrader before re processing the system. Possible to determine the existence of a leak and not its position in the system when using the pressure rise test it is recommended to use a helium leak detector with which the leaks may also be localized significantly faster. Use the line tap to access the system to diagnose problem.

Post a Comment for "The Best Leak Detection Test Is When The Refrigeration System Is"